|

Upload | Sign in |

|---|

An oxygen concentrator is a device providing oxygen therapy to a patient at minimally to substantially higher concentrations than available in ambient air. They are used as a safer, less expensive and more convenient alternative to tanks of compressed oxygen.

Oxygen concentrators operate on the principle of pressure swing adsorption of atmospheric nitrogen onto zeolite minerals.

At high pressure, nitrogen sticks to the surface of the zeolite. Because the zeolite is extremely porous, it has a very large surface area and can adsorb large volumes of gas. At low pressure, the nitrogen is released.

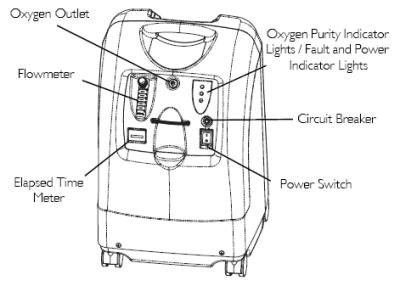

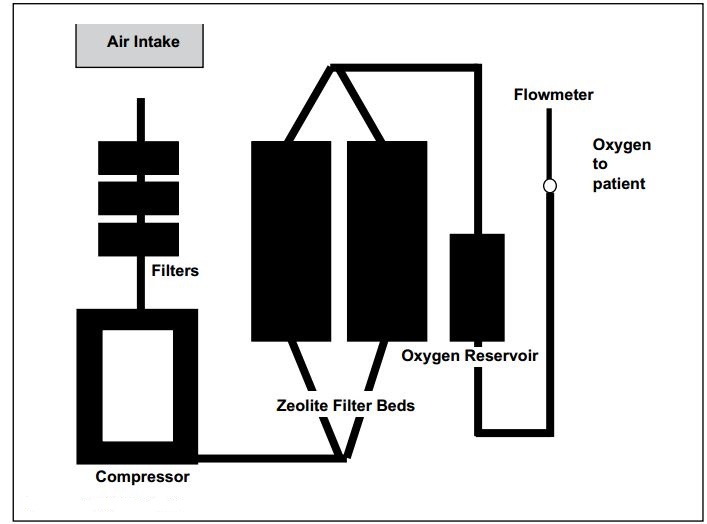

An oxygen concentrator has an air compressor, two cylinders filled with zeolite pellets, a pressure equalizing reservoir, and some valves and tubes.

The concentration process is cyclical with each cycle having two halves of equal duration. The cycle can be explained with respect to the first cylinder as follows. In the first half of a cycle, the first cylinder receives air from the compressor. The first half cycle lasts typically about 3 seconds.

During that time the pressure in the 1st cylinder rises from atmospheric to a few times normal atmospheric pressure (typically 20 psi/138 kPa gauge, or 2.36 atmospheres absolute) and the zeolite becomes saturated with nitrogen so that pumping in additional air would begin to reduce the oxygen concentration.

Part way through the first half of the cycle the gas in the 1st cylinder becomes close to pure oxygen (there are small amounts of argon, CO₂, water vapour, radon and other minor atmospheric components) and a valve is opened to allow that gas to start flowing to the pressure equalizing reservoir to which the patient oxygen hose is connected.

At the end of the first half of the cycle, there is another valve position change so that the air from the compressor is directed to the second cylinder. As what is in the first cylinder flows to the reservoir, the pressure in the first cylinder drops, and the nitrogen adsorbed on its zeolite begins to be released back into the gas, so that the oxygen concentration begins to drop.

Part way through the second half of the cycle there is another valve change whereby the gas still in the first cylinder is vented back to the surroundings i.e. to keep the concentration of oxygen in the pressure equalizing reservoir from falling below about 90%. The pressure in the hose delivering oxygen from the equalizing reservoir is kept steady by a pressure reducing valve.

Block diagram of oxygen concentrator

blog comments powered by Disqus